THAT MAKES

THE DIFFERENCE

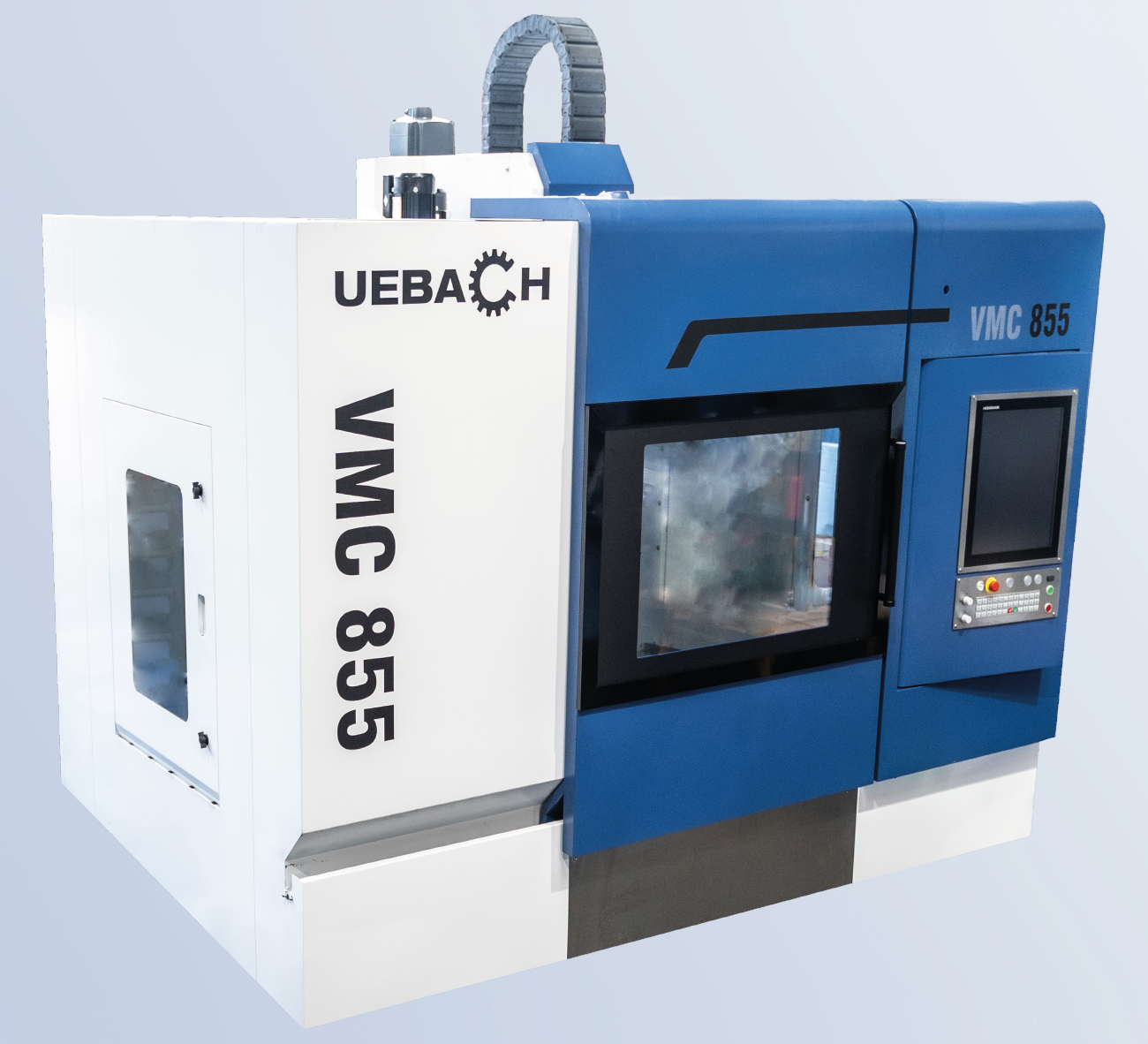

VMC 855

| Number of axes | 3 |

|---|---|

| Travel distance | |

| X (mm) | 800 |

| Y (mm) | 550 |

| Z (mm) | 550 |

| Main spindle speed (RPM) | 8000 |

| Position tolerance TP (mm) | 0,01 |

-

- Characteristics -

Milling spindle instead of cost-intensive motor spindle

Efficient power transmission with high performance enables a variety of machining applications. Particularly noteworthy is its robustness compared to a conventional motor spindle.

Optional integration of a robot

Optionally, the VMC 855 can be equipped with a robot for automatic workpiece loading. This integration increases the efficiency of manufacturing processes, reduces operating costs, and minimizes downtime.

Powerful drives

Thanks to powerful Siemens drives, the VMC 855 ensures fast and precise machining of workpieces made of various materials without compromising reliability.

Cost-effective all-rounder

The VMC 855 offers solid performance at an affordable price, making it a cost-effective solution for companies seeking a reliable machining center.

THAT MAKES THE DIFFERENCE

HG3-1200-1000

- Geometric stability and vibration-damping structure thanks to portal construction

- High cutting performance thanks to robust construction

- High dynamics thanks to powerful drives

- Optimum chip removal thanks to steep and generous walls in the cutting area

dimensioned chip conveyor - The machine can be optimally loaded with a crane thanks to the portal that moves far back

- No guidance, measuring systems or ball screws in the machining area

- Compact milling spindle unit (no motor spindle)

- Easy accessibility for service work

- Easy access to the machine table thanks to the overhanging guideway

- Quick and easy alignment of the machine thanks to the monoblock design

- Quadruple guided Z-axis

VMC 855

Milling spindle instead of cost-intensive motor spindle

Efficient power transmission with high performance enables a variety of machining applications. Particularly noteworthy is its robustness compared to a conventional motor spindle.

Optional integration of a robot

Optionally, the VMC 855 can be equipped with a robot for automatic workpiece loading. This integration increases the efficiency of manufacturing processes, reduces operating costs, and minimizes downtime.

Powerful drives

Thanks to powerful Siemens drives, the VMC 855 ensures fast and precise machining of workpieces made of various materials without compromising reliability.

Cost-effective all-rounder

The VMC 855 offers solid performance at an affordable price, making it a cost-effective solution for companies seeking a reliable machining center.

Assistance for self-help instead of expensive service technicians.

Frequently service tasks, maintenance, or repairs can be carried out mostly independently. Detailed service and repair instructions help you execute these tasks correctly. This concept was already taken into account during the desgin of the HG3 machine type, resulting in a logical and uncomplicated design. If desired, our qualified service staff can provide support.

When it comes to procuring spare parts, consumables, or other materials, we guarantee the most cost-effective and fastest solution. You have the option to utilize our extensive inventory or procure directly from the manufacturer.

Workspace

| XYZ axis travel | 1200 / 1000 / 800 mm |

|---|---|

| Distance spindle rigid table min. / max. | 1000 / 200 mm |

Star table

| Clamping surface table | 1300 x 1000 mm |

|---|---|

| 9 T-slots according to DIN 650 in the X direction | 18 H7 |

| 2 alignment grooves in the X direction | 18 H7 |

| Table load max. | 4000 kg |

Feed drive XYZ axis

| AC servo drives maintenance-free, digital | |

|---|---|

| Rapid traverse speed XYZ axis | 20 m/min |

| Feed force XYZ axis at 40% ED | 20,5 kN |

Main spindle drive

| milling spindle | |

|---|---|

| Tool holder | SK50 DIN 69 817 Big |

| Drive power at S1 | 50 kW |

| Speed range, infinitely variable max. | 1-8000 U/min |

| Torque at 25% ED | 690 Nm |

Tool magazine

| Magazine places, 1 plate | 32 |

|---|---|

| Tool diameter when fully equipped max. | 100 |

| Tool diameter with free neighboring locations max. | 160 |

| Tool length max. | 300 |

| Tool weight max. | 10 kg |

XYZ measuring system, direct

| Position tolerance TP according to VDI/DGQ 3441 | ≤ 0,007 mm |

|---|---|

| Machine weight approx. | 25.000 kg |

| CNC Control | TNC 640 Heidenhain |

Workspace

| Travel distance XYZ axis | 800 / 550 / 550 mm |

|---|---|

| Distance spindle table min. / max. | 120 / 670 mm |

Fixed table

| Clamping surface table | 800 x 550 mm |

|---|---|

| 5 T-slots according to DIN 650 | 18 H7 |

| Table capacity max. | 750 kg |

| Feed drive XYZ axis | 32 m/min |

Main spindle drive

| Main drive with milling spindle | belt-drive with CTS |

|---|---|

| Tool holder | BT40 (SK40) |

| Drive power at S1 100% | 17,5 kW |

| Speed range, stepless max. | 1-8000 rpm |

| Torque at S6 40% | 192 Nm |

Tool disk magazine

| Magazine slotes | 24 pcs. |

|---|---|

| Tool diameter when fully loaded max. | 78 mm |

| Tool diameter with free adjacent spaces max. | 120 mm |

| Tool length max. | 300 mm |

| Tool weight max. | 8 kg |

Measuring system XYZ, indirect

| Position tolerance TP according to VDI/DGQ 3441 | ≤ 0,01 mm |

|---|---|

| Machine weight approx. | 6.200 kg |

| CNC Control | TNC 620 Heidenhain / Siemens |

Coolant device

| Tank capacity | 270 Liter |

|---|---|

| Coolant pressure CTS | 20 Bar |

| External cooling | 4 nozzles |

| Milling air | available |

Dimensions

Bildtitel

Kollisionsüberwachung / Brankamp 2-Kanal

Button

Bildtitel

3D-Tastsystem / Heidenhain

Button

OPTIONAL EQUIPMENT.

- Milling spindle with spindle speed max. 5,000 rpm, 8,000 rpm

- Tool magazine for holding either 10, 20, 32 or 36 tools

▸ Additional tool positions on request - Coolant high pressure system Standard: 20 bar, Optional: 40 bar

- Collision monitoring / Brankamp 2-channel

- Camera for interior surveillance

- Triple machine vices with various clamping elements

- 3D touch system / Heidenhain

- Handwheel

- Extraction system

your direct

contact person

LUTZ UEBACH

CEO

Phone: 02745 9311-16

Fax: 02745 9311-30

Mail: info@maschinenbau-uebach.de

LUTZ UEBACH

CEO

Telephone: 02745 9311-16

Fax: 02745 9311-30

Mail: info@maschinenbau-uebach.de