VERTICAL

MACHINING CENTERS

HochGantry.

HG3 / HG5

The solid machine construction of the HG3/HG5 series in gantry design ensures geometric stability and vibration damping. In addition to the standard HG3/HG5 model with a travel range of 800 x 800 mm (X-Y axis), we expand your machinery options with solutions up to 1600 x 1200 mm. Drawing from decades of experience, high in-house manufacturing shares, and established standards, we have developed a machine type that excels in high machining performance and long-term precision.

HG3-800-800

| Number of axis | 3 |

|---|---|

| Travel distances | |

| X (mm) | 800 |

| Y (mm) | 800 |

| Z (mm) | 500 |

| Main spindle speed (rpm) | 12000 |

| Position tolerance TP (mm) | 0,006 |

HG5-800-800

| Number of axis | 5 |

|---|---|

| Travel distance | |

| X (mm) | 800 |

| Y (mm) | 800 |

| Z (mm) | 650 |

| Main spindle speed (rpm) | 12000 |

| Position tolerance TP (mm) | 0,006 |

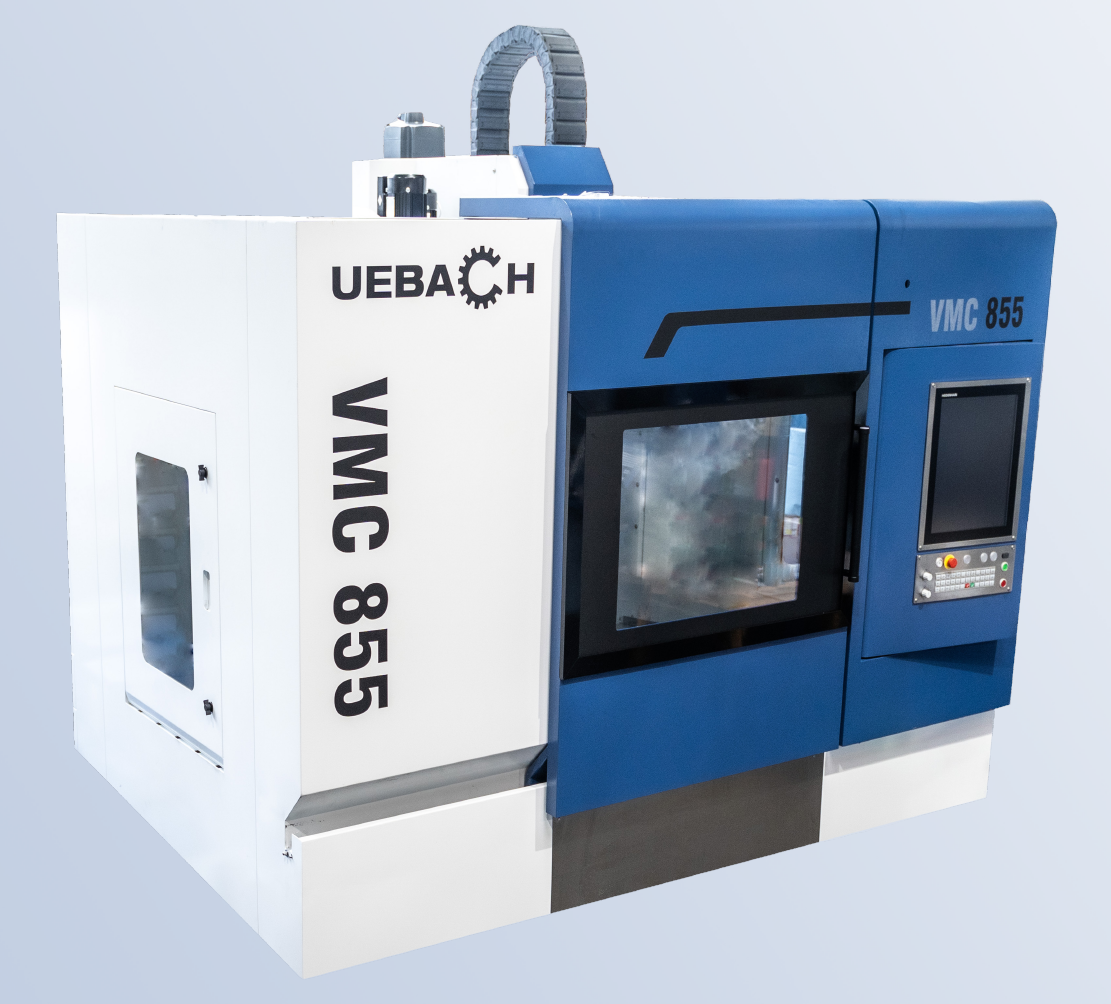

VMC 855

The

VMC 855 offers solid performance at an affordable price, making it a cost-effective solution for companies seeking a reliable and economical machining center. The optimal integration of robots can further enhance the efficiency of manufacturing processes, reduce operating costs, and minimize downtime.

VMC 855

| Number of axis | 3 |

|---|---|

| Travel distance | |

| X (mm) | 800 |

| Y (mm) | 550 |

| Z (mm) | 500 |

| Main spindle speed (rpm) | 8000 |

| Position tolerance TP (mm) | 0,01 |

VERTICAL

MACHINING CENTERS

VERTICAL

MACHINING CENTERS

HG3-1200-1000

| number of axes | 3 |

|---|---|

| traverse paths | |

| X (mm) | 1200 |

| Y (mm) | 1000 |

| Z (mm) | 800 |

| Main spindle speed (RPM) | 8000 |

| Positionstoleranz TP (mm) | 0,007 |

HG3-1600-1000

| number of axes | 3 |

|---|---|

| traverse paths | |

| X (mm) | 1600 |

| Y (mm) | 1000 |

| Z (mm) | 800 |

| Main spindle speed (RPM) | 8000 |

| Positionstoleranz TP (mm) | 0,007 |

The solid machine construction of the HG3/HG5 series in gantry design ensures geometric stability and vibration damping. In addition to the standard HG3/HG5 model with a travel range of 800 x 800 mm (X-Y axis), we expand your machinery options with solutions up to 1600 x 1200 mm. Drawing from decades of experience, high in-house manufacturing shares, and established standards, we have developed a machine type that excels in high machining performance and long-term precision.

HG3-800-800

| Number of axis | 3 |

|---|---|

| Travel distances | |

| X (mm) | 800 |

| Y (mm) | 800 |

| Z (mm) | 500 |

| Main spindle speed (rpm) | 12000 |

| Position tolerance TP (mm) | 0,006 |

HG5-800-800

| Number of axis | 5 |

|---|---|

| Travel distances | |

| X (mm) | 800 |

| Y (mm) | 800 |

| Z (mm) | 650 |

| Main spindle speed (RPM) | 12000 |

| Position tolerance TP (mm) | 0,006 |

The

VMC 855 offers solid performance at an affordable price, making it a cost-effective solution for companies seeking a reliable and economical machining center. The optimal integration of robots can further enhance the efficiency of manufacturing processes, reduce operating costs, and minimize downtime.

VMC 855

| Number of axis | 3 |

|---|---|

| Travel distance | |

| X (mm) | 800 |

| Y (mm) | 550 |

| Z (mm) | 550 |

| Main spindle speed (rpm) | 8000 |

| Position tolerance TP (mm) | 0,01 |